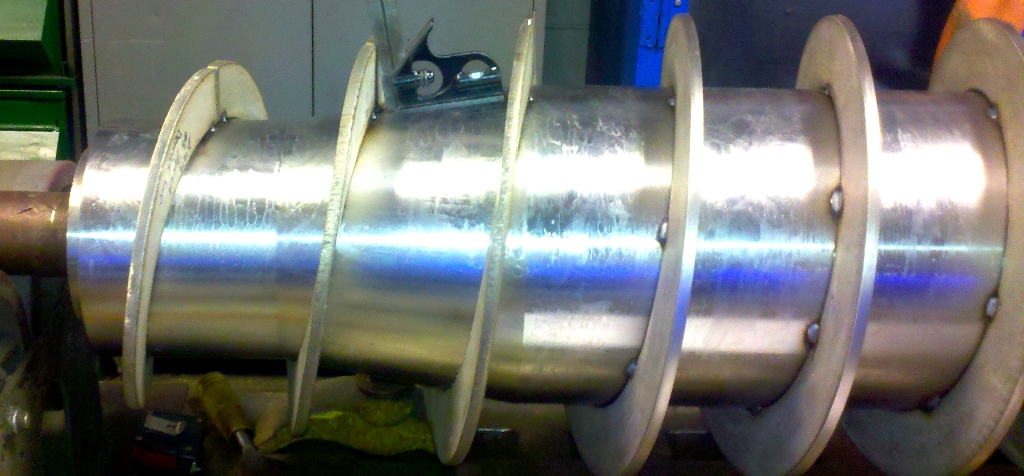

A sectional flight is an individual turn, wrap, or fragment of wraps shaped into any helix. The cross-area of sectional twist drill flight is the equivalent from the OD towards ID. Sectional flying was regularly utilized when the tallness, or web, of a flight, is bigger than what could be created with level bar into helicoid flight. Twist drills give a basic capacity to the movement of materials. Read on to know more about sectional flights.

Smooth activity relies on the accuracy of the wood screw balances or edges, generally eluded as flights. There were two primary procedures utilized in the formation of wood screw flights. They are helicoid and sectional. Arrangement of each kind includes an alternate procedure and produces special qualities. A trip is a twist drill cutting edge exclusively framed from plate steel to a helix.

The procedure for making a voyage goes as described. The procedure starts with a bit of plate steel piece into a doughnut shape with a predefined inside width and outside measurement. A press forms them into a type of helix. Every helix is a part joined to make a progression of flights. Last arrangement of the wood bolt incorporates appending the completed consistent helix to a pole.

These are of uniform thickness from the ID edge toward the OD edge. The flying procedure takes into account a more noteworthy variety in a plan, material thickness, or material utilized, however, maintenance is required to shape them into a completed wood screw. As opposed to an arrangement in segments, helicoid flights are made as a spiral that is shaped from a solitary bit of carbon or tempered steel.

This procedure incorporates moving machines with cone-molded bites the dust are set to explicit ID and OD measurements to change a segment of steel stock through folding it into a solitary ceaseless helix. This pressure procedure causes OD edges to wind up more slender rather than the consistency of some other kind. Shaping a solitary helix sets aside time and cash, yet there are restrictions with regards to the material.

This includes the structure and material thickness utilizing this strategy. Custom flight utilize exceptionally propelled hardware and procedures to work with different kinds of tempered steel, scraped area opposing steel and nickel compounds in the formation of all our exactness. The majority of the procedures outperform CEMA models.

They can create any kind including lace voyages or helicoid voyages in different ODs, pitches, and thicknesses. They can give sectional and helicoid trips to best-fit client applications. They likewise highlight esteem included administrations, for example, structure building, get together, and an assortment of completions and medicines. The flight could be created to a wide scope of sizes.

The measurements are commonly constrained by formability of base material. However, they could work with you to defeat these impediments using multi-piece segments. They additionally make a trip with jolt opening examples for mounting shoes or blades, darting flight portions to mounting focuses or joining fragments to one another.

They routinely cut and structure these flights with spaces, indents, saw teeth, tabs or cut and overlap arrangements, or a blend of these highlights. They can program our plasma machinery to cut spaces with a precut decreased OD, decreased ID or the two widths decreased and journey that fit a square focus shaft.