Image Source: Google

Laser manufacturing services have revolutionized the way products are created, offering precision, speed, and versatility that traditional manufacturing methods cannot match. From cutting and welding to engraving and marking, laser technology has opened up a world of possibilities for industries across the board. In this article, we will explore the power of laser manufacturing services and how they bring concepts to life with incredible accuracy and efficiency. Refer Link: https://www.lasermicromachining.com/.

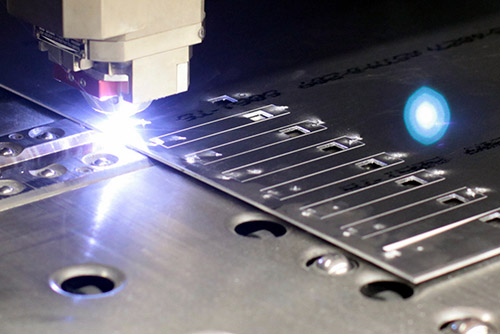

The Basics of Laser Manufacturing

Laser manufacturing involves the use of laser technology to cut, weld, engrave, or mark materials with a high level of precision. The process utilizes a focused laser beam to remove material layer by layer, resulting in clean and accurate cuts or marks. Laser manufacturing services are widely used across various industries, including automotive, aerospace, electronics, and healthcare, to create intricate components and products.

Advantages of Laser Manufacturing Services

- Precision: Laser technology offers unmatched precision, allowing for intricate designs and tight tolerances that are not possible with traditional manufacturing methods.

- Speed: Laser cutting and welding are faster than many other manufacturing processes, significantly reducing production times and increasing efficiency.

- Versatility: Laser technology can be used on a wide range of materials, including metals, plastics, glass, and ceramics, making it a versatile solution for diverse manufacturing needs.

- Quality: Laser manufacturing produces high-quality finishes with minimal to no post-processing required, resulting in cost savings and faster time to market.

- Cost-Effective: While the initial investment in laser technology may be higher, the long-term cost savings in production and maintenance make it a cost-effective solution for many businesses.

Applications of Laser Manufacturing Services

From prototyping to mass production, laser manufacturing services are used in a variety of applications to bring concepts to life. Here are some common applications of laser technology in manufacturing:

Prototyping

- Rapid prototyping: Laser cutting and engraving are used to quickly create prototypes for testing and evaluation before full-scale production.

- Iterative design: Laser technology allows for easy modifications and adjustments to prototypes, speeding up the design iteration process.

Custom Fabrication

- Custom parts: Laser cutting and welding services are used to create custom parts and components with precise specifications.

- Personalization: Laser engraving and marking are utilized to add logos, text, or graphics to products for branding and personalization.

Mass Production

- High-volume production: Laser technology is employed for mass production of components and products, offering consistent quality and efficiency at scale.

- Just-in-time manufacturing: Laser manufacturing services enable just-in-time production, reducing lead times and inventory costs for manufacturers.

The Future of Laser Manufacturing

As technology continues to advance, the future of laser manufacturing services looks brighter than ever. Innovations in laser technology, such as femtosecond lasers and additive manufacturing, are pushing the boundaries of what is possible in manufacturing. Here are some key trends shaping the future of laser manufacturing:

Improved Speed and Efficiency

- Advancements in laser technology are leading to faster processing speeds and higher efficiency, allowing for even quicker production times and lower costs.

- Automation and Robotics: Integration of laser systems with automation and robotics is streamlining production processes and increasing productivity in manufacturing.

Enhanced Materials Processing

- New materials: Laser technology is expanding to process a wider range of materials, including composites, ceramics, and even biological tissues, opening up new possibilities for product design and manufacturing.

- Nano-scale machining: Laser systems are being developed for nano-scale machining, enabling ultra-precise manufacturing at the smallest level.

Sustainability and Environmental Impact

- Green manufacturing: Laser technology is inherently more eco-friendly than traditional manufacturing methods, with reduced waste, energy consumption, and environmental impact.

- Recycling and Upcycling: Laser manufacturing services are being used for recycling and upcycling materials, contributing to a more sustainable and circular economy.

Overall, laser manufacturing services play a crucial role in bringing concepts to creation with precision, speed, and versatility. From prototyping to mass production, laser technology continues to push the boundaries of what is possible in manufacturing, paving the way for a more efficient and sustainable future.